The promotional products industry has its own set of unique terms and processes that help define everything from decoration methods to product options. Here’s a quick glossary of essential terms to guide you through the world of promo products with clarity and confidence.

Design

Brand Kits

A brand kit is a concise version of a more comprehensive brand style guide, which outlines brand assets and design choices in detail. A brand kit is a collection of the visual elements of your brand: the color palette, logo(s), and typography.

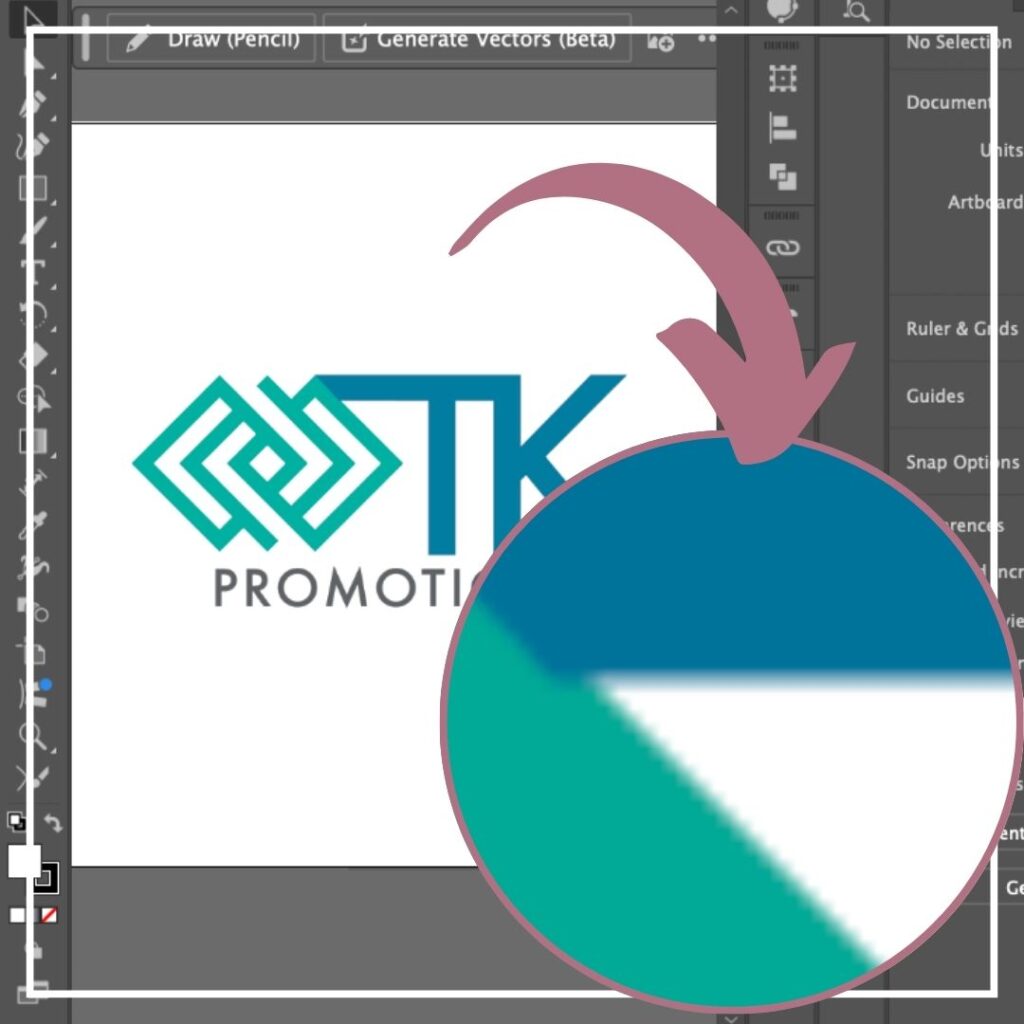

Raster

Raster files are images built from pixels — tiny color squares that, in great quantity, can form highly detailed images such as photographs. The more pixels an image has, the higher quality it will be, and vice versa. The resolution of a raster file is referred to in DPI (dots per inch) or PPI (pixels per inch). If you zoom in or expand the size of a raster image, you start to see the individual pixels. Common file types include .JPG, .JPEG, .PNG, .GIF, and .BMP.

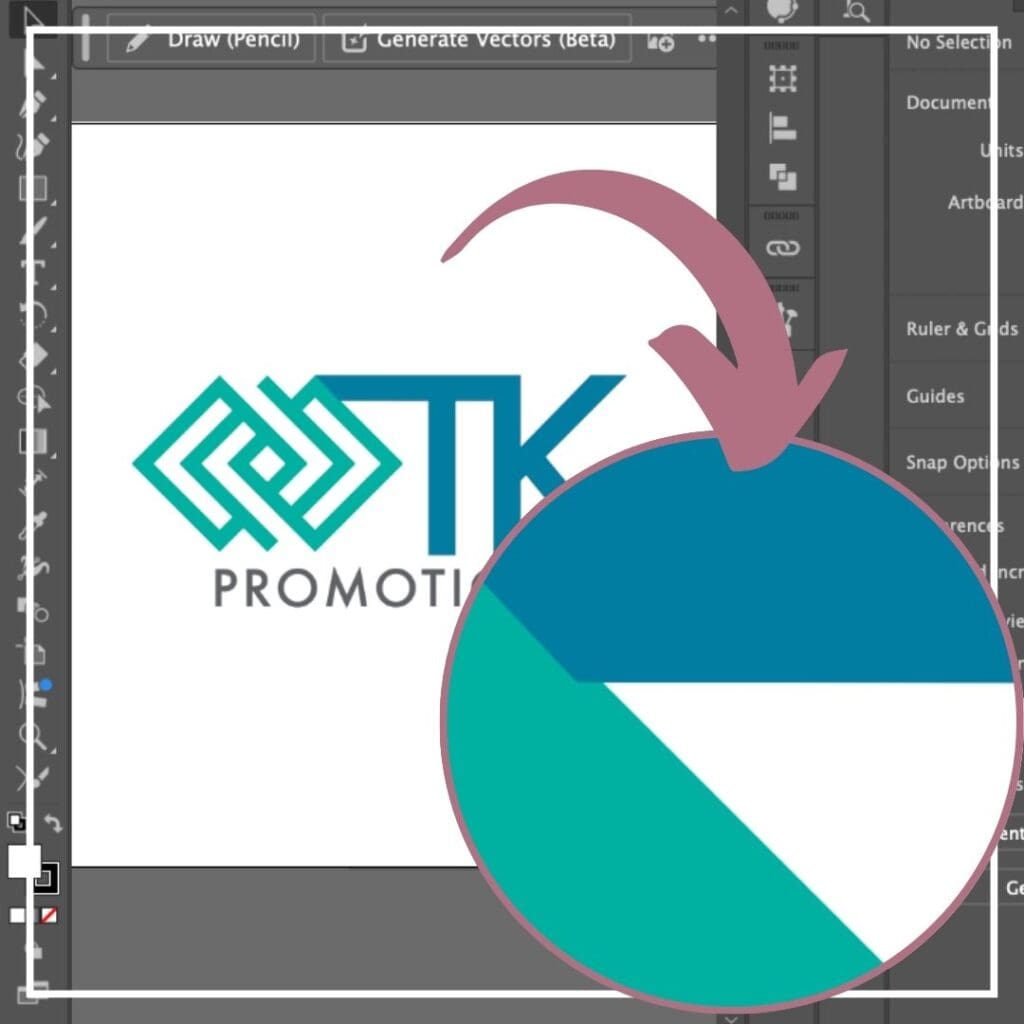

Vector

Vector graphics are points, lines, curves and shapes that are based on mathematical formulas. When you scale a vector image file, it isn’t low resolution and there’s no loss of quality, so it can be sized to however large or small you need it to be. This is helpful for building promotional product files, from a small imprint on a pen to a large outdoor banner. Common file types include .AI, .SVG, .EPS, and .PDF.

Pantone and Pantone Matching System (PMS)

PMS, or Pantone Matching System, is a standardized color-matching system used globally in design, printing, and manufacturing to ensure consistent colors across various materials and production processes. Each Pantone color is assigned a unique code, allowing brands to maintain their specific hues across all branding elements, from digital screens to printed items. This consistency is vital for brand identity and recognition.

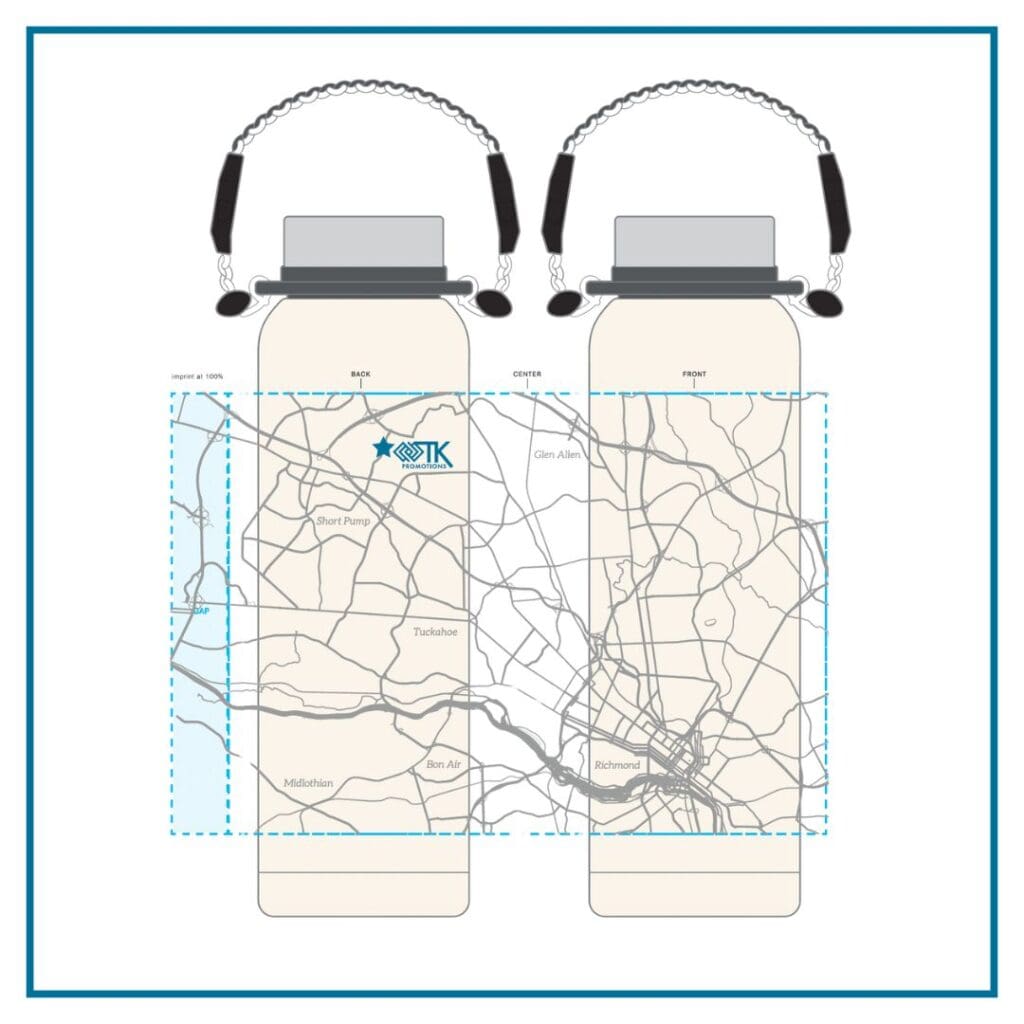

Virtual

A virtual is a digital mockup showing how a logo or design will look on a promotional product. It helps clients visualize branding options before production by showing logo placement, color, and scale in a realistic way.

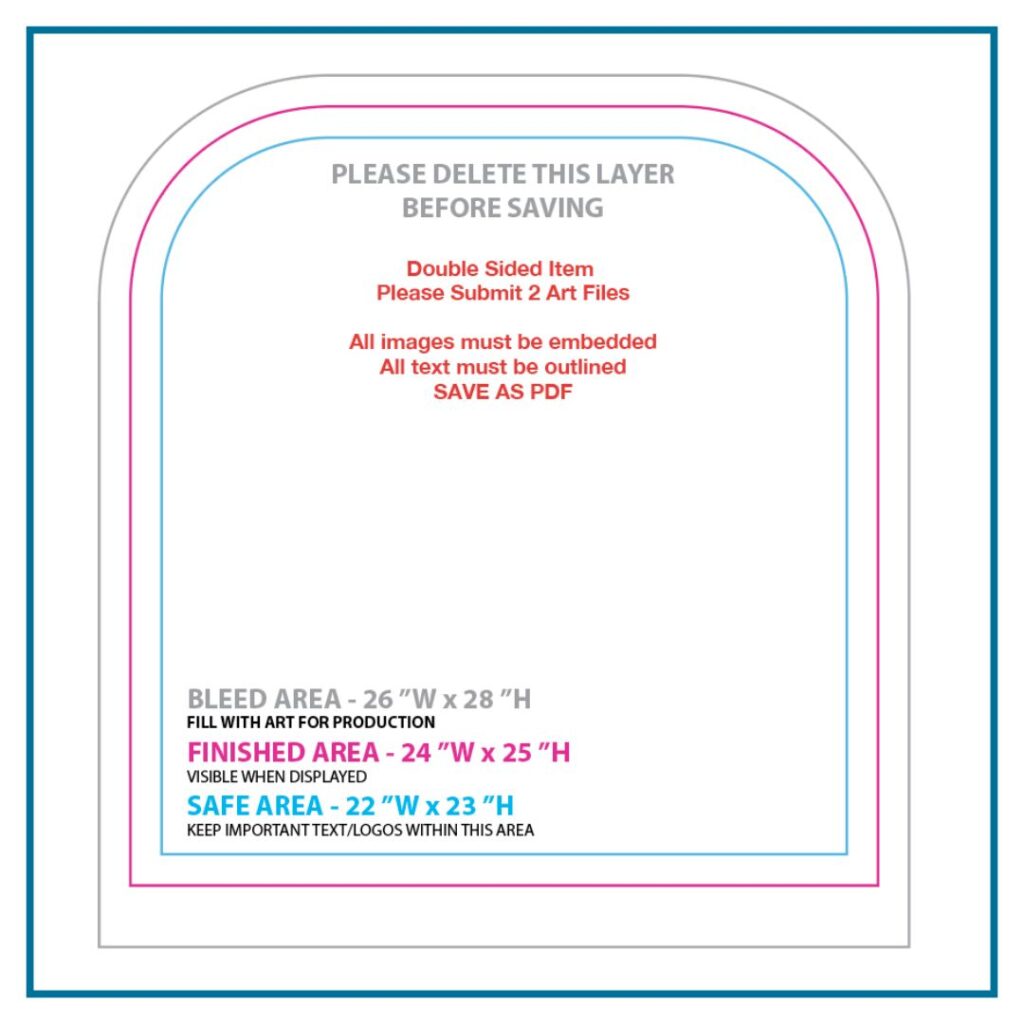

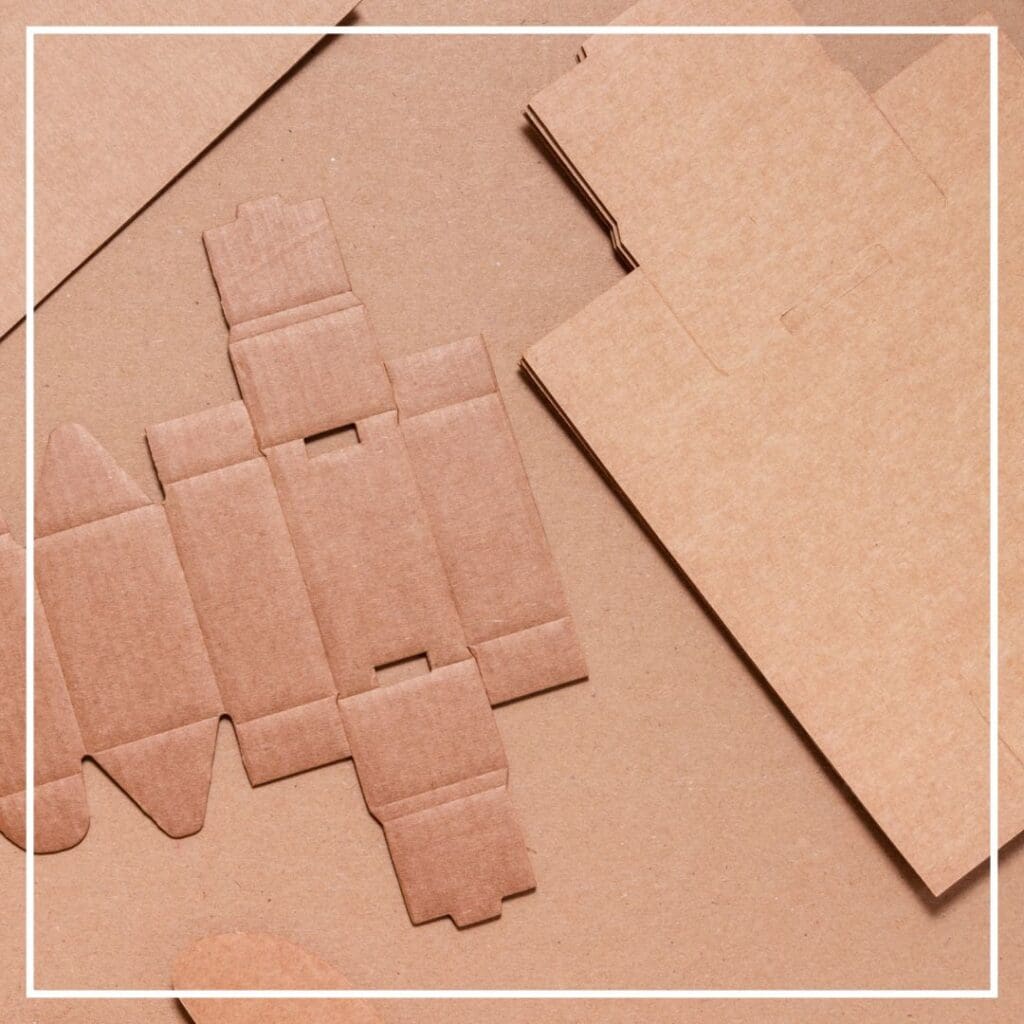

Bleeds

For products like signage and cardboard packaging, printers cannot print right to the edge of the material. To create that effect, the printer must use material that is larger than the actual product size and then trim off the excess. This creates an edge-to-edge design effect. A bleed is the space bigger than the product dimensions that will be trimmed off.

Step and Repeat

A design that involves a repeating, diagonal pattern, often with a logo. Step and repeat designs are often used on large banners or as a publicity backdrop used primarily for event photography.

Production

Hard Goods

Hard goods are physical, long-lasting items like branded pens, notebooks, or custom water bottles. These tangible products offer lasting brand exposure and are popular in promotional marketing due to their practical use. They are ideal for building brand recognition through everyday items.

Dupe

A very close and more affordable substitute to a name brand retail product. Sourcing a dupe requires care to insure it matches up in appearance as well as performance and quality.

Blank Sample

A blank sample is a plain version of a promotional product without any logo or additional design, used for evaluating the item’s quality and appearance before ordering. It’s helpful for quick comparisons and hands-on inspection.

In-Hands Date

This is crucially important for project management and execution. Our team will ask what your “in hands date” is to better understand your expectations for when you need to receive the products you’ve ordered.

Fulfillment

The process of managing the distribution of promotional products including inventory management, processing orders, packaging, shipping, tracking, and delivery.

Overseas Sourcing and Production

Overseas sourcing and production involve obtaining items from international manufacturers, often enabling greater customization options, such as zipper colors and decoration capabilities, as well as lower prices. However, this approach usually comes with significantly longer lead times, often requiring a minimum of three months for production and delivery.

Spec Sample

A spec sample, or speculative sample, is a printed product featuring a client’s logo, typically created to showcase branding ideas before committing to an order. Often initiated by a sales rep during project planning, it allows clients to visualize a custom product with their logo. While there is usually a cost, the TK Promotions team can often negotiate a free spec sample on your behalf.

Pre-Production Proof

A pre-production proof is a digital image showing your item with the logo positioned exactly as it will be printed, providing a final visual check before production begins. It ensures accuracy in logo placement, color, and design details.

Pre-Production Sample

A pre-production sample is a printed sample of an item from an existing order, allowing clients to review the final design before full production. This step is crucial for large orders or highly customized products, as it ensures accuracy in design and print quality before proceeding.

Set Up Charges

Set-up charges are fees applied by the factory to prepare the equipment and materials needed to print your items. These cover tasks like creating screens, plates, or molds, ensuring accurate logo placement and design.

Minimum Order Quantity

The smallest amount of product a supplier is willing to produce in a single order.

Overruns and Variance

When larger orders are run, suppliers often have a 10% overrun allowance to ensure that they produce enough product for the order. The supplier can ship 10% more or less than the requested amount within their allowance. If an exact quantity is requested, that is possible for a small fee.

CLC Licensing and Affinity Licensing

The University/College, Trademarks and Licensing teams at CLC and Affinity aim to positively promote the institution’s image, protect its trademark rights and generate royalty revenue. Creating and maintaining positive relationships with manufacturers and retailers is an integral part of each program’s overall success. This relationship helps to ensure that products bearing the marks of the university are of the highest quality and satisfy the consumer demand.

Supplier Shipping

At TK Promotions, we offer a comprehensive range of services to cover all your promotional product needs. In doing so we work with respected suppliers located across the country. Each supplier ships directly from their warehouse to our clients directly as opposed to coming directly from TK Promotions.

Polybagging

The process of wrapping promotional products in a plastic bag for protection and preservation during storage, shipping and distribution.

Decoration

Imprint Area

The imprint area refers to the specific location and dimensions on an item where you can place a printed logo or decoration. It’s important for clients to note that smaller imprint areas may not accommodate complex logos or large amounts of text effectively.

Decoration Method

The decoration method refers to the technique used to print designs on your items, with various options available for each product. This allows for flexibility in achieving the desired look and feel for your promotional materials.

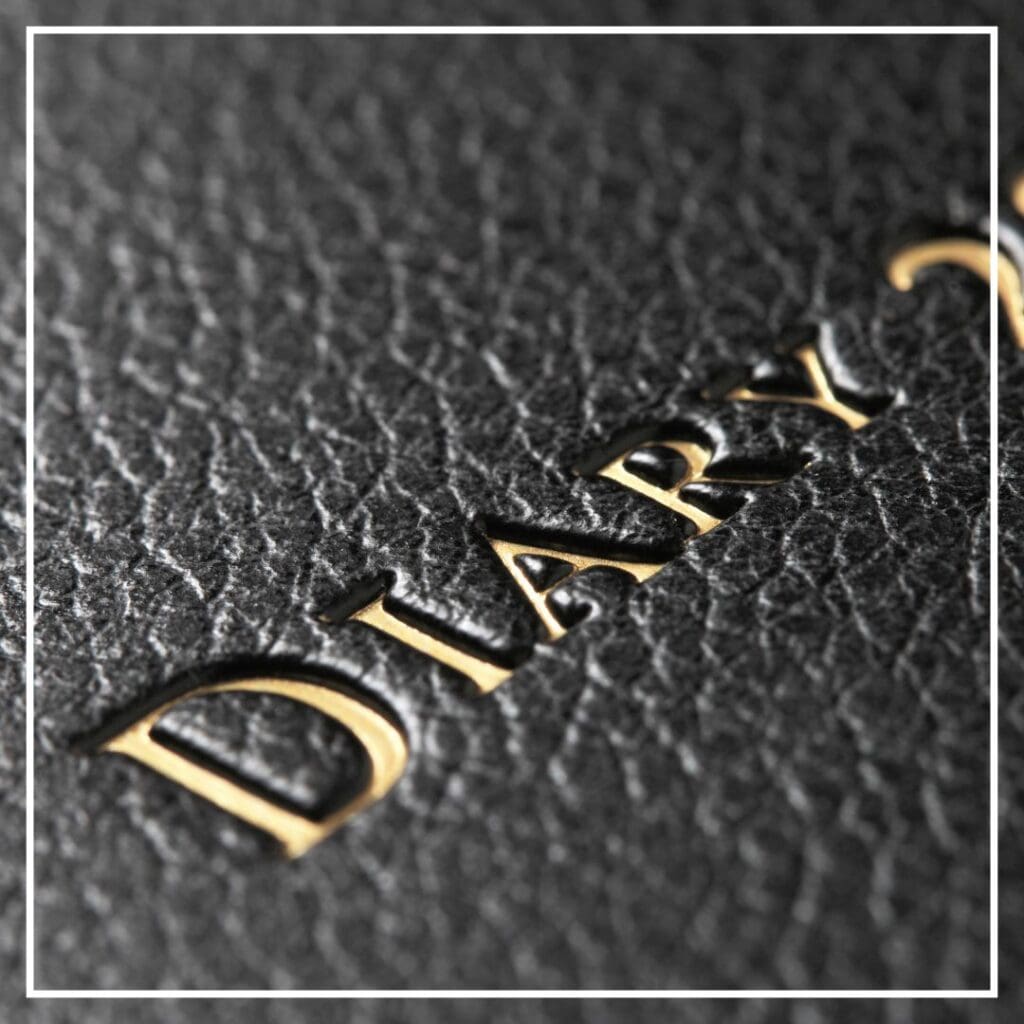

Embossing

An embossed imprint is a design that’s raised up from the material by pushing it through a metal plate from underneath with another plate on top. Embossing results in a design that pops from the surface.

Debossing

Debossing is an imprint method that pushes a metal plate in the shape of your design, onto the front of the product material. The design is sunken or recessed into the material.

Die-Cut

Die cutting is a process that uses sharpened steel blades to cut specific shapes, patterns, and designs into materials like paper or cardstock. It operates like a cookie cutter, where a preformed shape with a sharp edge is pressed through a substrate using pressure.

Die-Struck

Often used for pins or metal products, a flat, metal blank is stamped between two steel dies under intense pressure. One die has a recess with the intended pin shape, while the other has a protruding shape to stamp that form into the blank. Striking the blank under high-pressure transfers and holds the shape precisely.

Die-Cast

In die casting, liquid metal is injected into a steel mold under high pressure to create a pin. Once the mold cavities fill, the metal cools and solidifies into the intended shape before being removed.

Embroidery

Embroidery is a process where machines use digital files to stitch designs onto fabric. A design is created in a computer program and uploaded to the embroidery machine, which then uses a needle and thread to apply the design in various colors and complex patterns.

Screen Printing

Screen printing involves creating a stencil on a mesh screen and pushing paint or ink through it to transfer the design onto products like apparel and bags. This quick and popular method is effective for large runs, but it may have limitations regarding the number of colors used and the long-term durability of the imprint.

Four Color Process

Four-color process is a high-quality screen printing technique that reproduces photographic images on apparel using four ink colors: cyan, magenta, yellow, and black. This method allows for a wide range of colors and detailed designs, making it ideal for vibrant and intricate prints.

Direct To Film Transfer Printing (Direct Transfer)

A specialized film is created to transfer a design onto fabric. Using a heat press, the design is applied, resulting in a high-quality, vibrant print.

Sublimation

Unlike traditional printing methods, sublimation involves using heat and pressure to turn inks into gas, which then penetrates the material for a permanent imprint. This process bonds the ink with the fabric rather than sitting on top, resulting in a high-quality, vibrant design that is much less prone to cracking or fading.

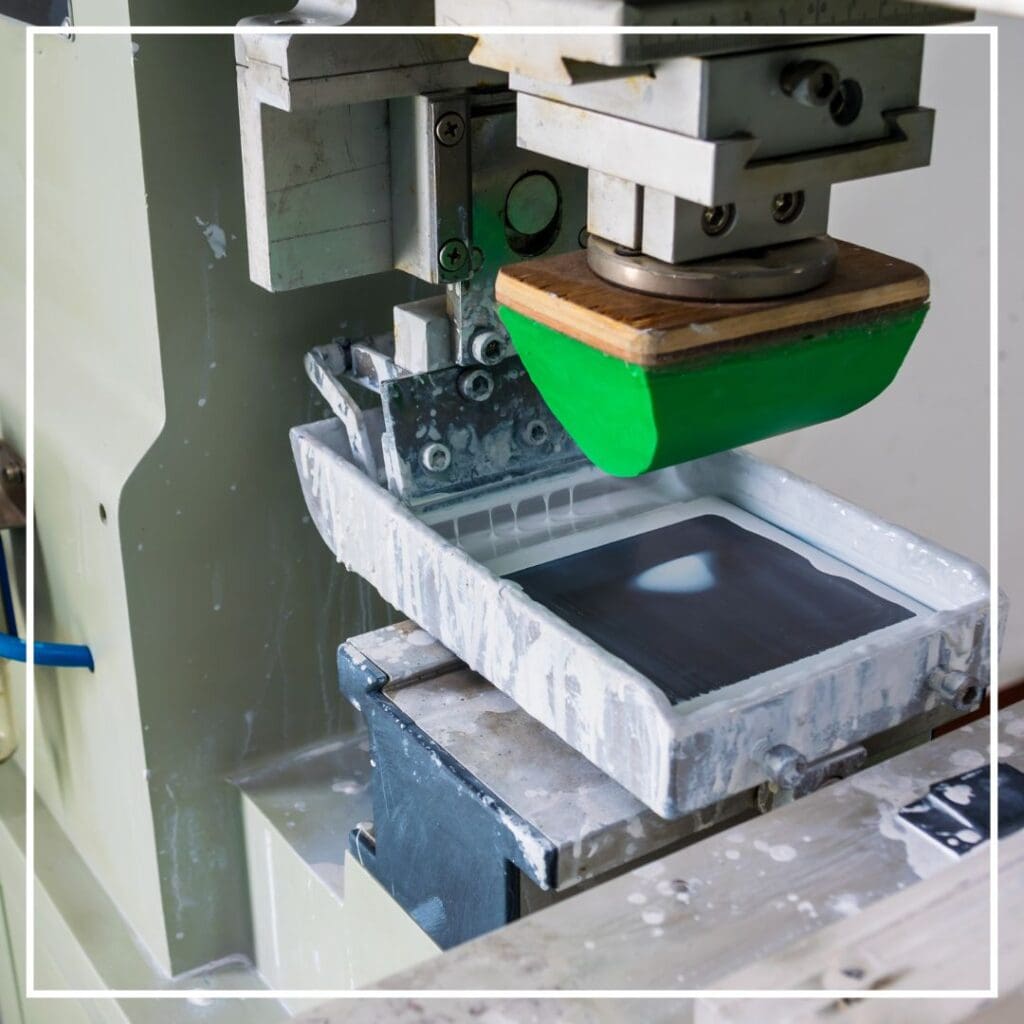

Pad Printing

Pad printing is a technique where a silicone pad holds the blank promotional product steady while pressing into an ink plate shaped to match the logo or artwork. The pad then transfers the ink onto the item, which is left to air dry. This method is commonly used for items like pens, travel mugs, and other hard goods.

Feeling inspired? Reach out, and let’s turn your marketing vision into a success!